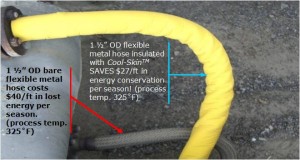

Reduce energy cost by 68% with Cool-SkinTM insulation sleeve on hot oil “jumper” hoses.

A typical Hot Mix Asphalt (HMA) plants makes use of hundreds of feet of flexible metal “jumper” hoses to transfer hot oil across connection flanges. These hoses are frequently overlooked by insulation contractors as they usually have a tight bend radius and they are difficult to protect. In addition the neglected jumper hoses are often considered unimportant because they represent a small portion of the hot oil system. The reality is that these un-insulated lines result in huge inefficiencies and cost thousands of dollars in wasted energy. This would is similar to leaving a window open all winter long. It just doesn’t make good sense.

Worbo has developed an effective thermal insulation solution that enables HMA plants to recover significant heat losses on small diameter and tight radius hoses with ease. Introducing Cool-SkinTM sleeve!

Unlike traditional methods such as mineral wool and hard aluminum cladding, Cool-SkinTM is easy to install and does not require expensive insulation contractors. A hook and loop self gripping fastener is incorporated into its design allowing operations staff efficient access to process lines while performing maintenance procedures or trouble-shooting system components. Once line interruption is complete, Cool-Skin™ is simply re-installed in a few short seconds.

An additional important and impressive benefit to the Cool-SkinTM technology is that it incorporates a closed cell insulating structure that will not absorb water or moisture making it an effective insulator even in wet conditions.

Ongoing field monitoring has proven that insulating a flexible metal hose (1 ½” OD) with Worbo’s Cool-Skin™ sleeve at a typical HMA plants will reduce heating cost an average of $30 for every foot of jumper hose in just one short seven (7) month operating season. In most cases Cool-Skin™ pays for itself within the first four (4) months of installation.

Contact the Worbo team to learn more about how Cool-SkinTM can reduce energy costs at your HMA plant.