It is well known that providing insulation for hot process lines and equipment makes good economical sense by reducing operating costs at a time when energy prices are skyrocketing. A Worbo insulation system could easily pays for itself within a few months of installation. However, often what motivates our customers to implement an insulation system is not simply economics but rather safety concerns. In today’s market place an increasing number of responsible industrial companies are committed to ensuring the safety of their valuable human resources.

Hot process lines and equipment represent a significant safety hazard and when it comes to high-temperature operations “safe touch” conditions are key to establishing a safe work environment.

ASTM C1055 (Standard Guide for Heated System Surface Conditions that Produce Contact Burn Injuries) has determined that the most probable time for a worker to come into contact with a hot surface in an industrial setting is approximately five seconds. ASTM C1055 further states that the average person can touch a hot surface of 140oF for up to five seconds without sustaining irreversible damage. For this reason 140oF is widely recognized to be the “safe touch” condition. However, often in an environment with high ambient temperatures or where there is an increased risk of employee contact, many plant managers and process engineers prefer to implement a “safe touch” temperature of 120oF to further minimize the risk of injury.

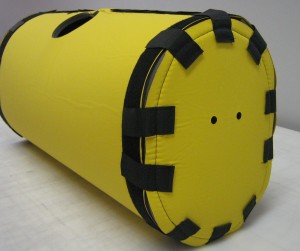

Worbo offers several options and thousands of variations of our high temperature “safe touch” insulation covers for virtually any configuration of equipment. Often equipped with straps, velcro® or fasteners for ease of installation and supplied in the proper thickness a Worbo insulation cover is a very effective solution for reducing surface temperatures down to ASTM C1055 recommendations and below.

Typical Worbo “safe touch” Insulation Covers

Determining the best “safe touch” insulation system

Once a Worbo customer has identified the need for “safe touch” insulation it’s up to the Worbo engineering team to design the best possible system. Choosing an insulation solution will be established in consideration of the following parameters:

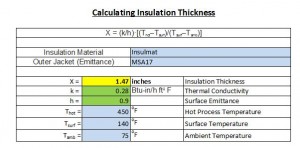

Insulation Material – The effectiveness of an insulation solution is greatly dependent on the type of insulation material. All materials have temperature limitations and it is important to select a material that is capable of withstanding the environmental exposure temperatures. In addition it is important to select an insulation material that has a low thermal conductivity to maximize its effectiveness as an insulator.

Ambient Temperature – This is the temperature of the air in the space surrounding the insulation. A higher ambient temperature will lead to a higher temperature on the outer surface of the insulation.

Air Flow – In an area where there is significant air flow this will result in a substantial decrease in the surface temperature of the insulation. Often in the interest of safety the Worbo engineering team will ignore this parameter to ensure that the insulation is effective in providing a “safe touch” conditions in still air environments.

Outer Jacket Material – The outer jacket material of an insulation cover will release absorbed heat through a property called thermal emissivity. Materials that exhibit high emissivity will release more heat away from its surface than materials with lower emissivity and therefore produce a lower surface temperature. Materials such as Worbo’s MSA17 have a high emissivity and are a good choice for the outer jacket of an insulation system to produce “safe touch” conditions.

Insulation Thickness – The most significant design parameter in establishing a “safe touch” insulation solution is in most cases is the thickness of the insulation. Intuitively, it makes sense that the thicker the insulation, the more effective it will be a reducing the surface temperature down to “safe touch” conditions. However, it is important to note that the relationship between the thickness of the insulation and the surface temperature is not linear. In other words, doubling the insulation thickness will not double its effectiveness as an insulator.

Below is a simplified calculation to demonstrate how the thickness of a Worbo “safe touch” insulation system may be determined in consideration of the above noted parameters.

If your employees are exposed to a high temperature hazard and you are not sure what the best option is, call the engineering team at Worbo and they will be happy to help you. It’s what they do best!