Here at Worbo Inc. we pride ourselves on providing top quality custom fabricated high temperature insulation components for process lines and equipment. In our view, an essential characteristic of a successful insulation cover is that it must be user friendly. It should be easy to install and easy to remove and reinstall for maintenance. This eliminates the need for expensive insulation contractors and minimizes the loss of valuable production time. Ease of installation is often achieved through the implementation of simple and effective mechanical closures. At Worbo we offer a wide range of fastening systems to create easy to install insulation components that are suitable for thousands of high temperatures applications. Here’s how we “hold it together”.

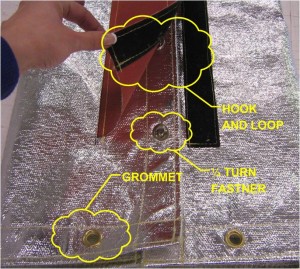

Grommets and Wire Ties

This method for securing a Worbo insulation component in place employs the use of high temperature grommets in combinations with wire ties. It often consists of a series of grommets (ranging in diameter from ¼” ID up to 1” ID or larger) placed around the perimeter of an insulation component. Grommet holes on one side of an insulation cover will line up with adjacent grommet holes on the opposite side of the cover and will be joined together with a wire tie or metal banding. In many cases this is can be the most cost effective solution.

Grommets and Carabiners

In the case of a high temperature insulation curtain application, grommets may be used in combination with spring snap carabiners. This mechanism will enable a curtain to be suspended from a supporting rod or structure and it will allow for the curtain to slide back and forth creating an access opening when the curtain is not in use. A simple “S” hook also works well for this application as a substitute for the carabiners.

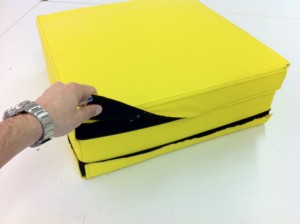

Hook and Loop

This is one of our favorites and it comes standard on our Cool-SkinTM sleeve line of products. High temperature hook and loop (Velcro®) is a fantastic closure option that may be exploited on a huge assortment of insulation components. It’s simple and dynamic. We offer hook and loop in a broad array of widths from as narrow as a ½ inch wide up to six inches wide and beyond. It is available in various profiles that can maximize gripping strength or maximize opening and closing cycles depending on the application. A hook and loop closure provides a very good seal to allow for maximum heat retention and it can be incorporated into virtually any configuration of insulation cover. Thanks for the invention George de Mestral, great idea!

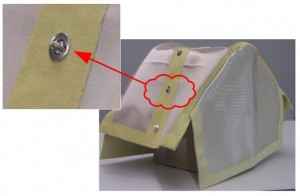

¼ Turn Fasteners

Another great option is the ¼ Turn or Common Sense fasteners. These are great for creating a strong mechanical union between two mating surfaces. They are particularly effective in situations where ease of installation and maximum connections strength are critical. Here’s how it works….a small turnbutton post is secured to the perimeter edge along one side of an insulation cover. This post is then inserted through an oval eyelet mounted on the opposite side of the cover and then it is simply rotated 90 degrees to lock it in place creating a mechanically positive attachment. The photo below illustrates how this closure works on a trolley skirt installed on an overhead crane festoon protection system.

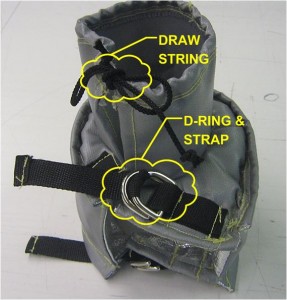

D-rings and Straps

D-rings and straps are a fantastic option for providing a very snug fit between an insulation sleeve and a hot process line to ensure that heat retention is maximized. This mechanism works in a similar fashion to a chin strap on a standard motorcycle helmet. A high temperature tension strap is inserted through two d-rings that are secured to an insulation component. The strap is then fed back between the two d-rings and pulled tightly. By drawing the strap firmly, this mechanism ensures that the insulation component will fit tightly around the process line. This system also allows for some flexibility with respect to the size of the components being insulated and often a single insulation part may be used for multiple process lines. In this scenario an insulation sleeve is overbuilt to accommodate a largest possible shape and then it may be drawn in with the straps and d-ring arrangement to fit snugly around a smaller line. In many cases this is a one size fits all solution.

Lacing

This is another great low tech option that offers an effective and inexpensive solution for securing an insulation component in place. As with the d-rings and strap method the lacing option will provide a forgiving range of adjustment to allow for a tight fit around various sizes and shapes of equipment.

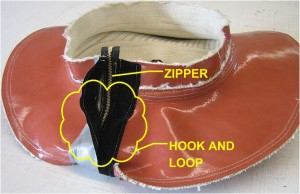

Zippers

A high temperature zipper is yet another option for securing an insulation component in place. Below is a photo of a zipper that has been effectively utilized in a bellows style insulation boot. The boot has been designed to protect a hydraulic cylinder from molten splash and it is easily installed without disassembling any of the heavy equipment. Notice that the zipper has been secured to the boot in a spiral fashion along its length. This allows for the zipper to be offset between each the corrugations of the bellows to ensure that when the bellows is collapsed it occupies the minimum amount of space.

Combination of Different Closure Mechanisms

When one type of closure just won’t do to the trick we can easily incorporate multiple closure mechanisms into a custom fabricated high temperature insulation component for maximum thermal protection and minimum heat loss.

At Worbo one of our primary business objectives is customer satisfaction. We believe we can achieve this through providing high quality and cost effective insulation components that are easy to install. Our expertise and experience with a large assortment of closure mechanisms and fastening systems allows us to provide easy to install components that satisfy our customers.